Info

Useful Links

Connect Us

Copyright Inline Solutions Inc. 2017.

All rights reserved.

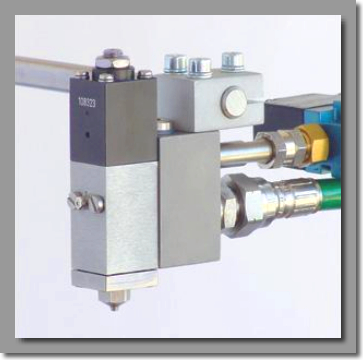

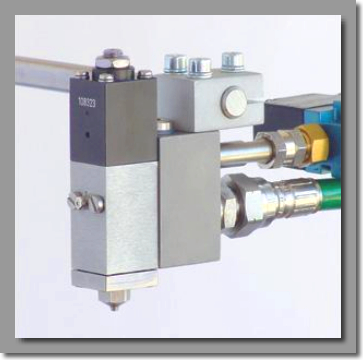

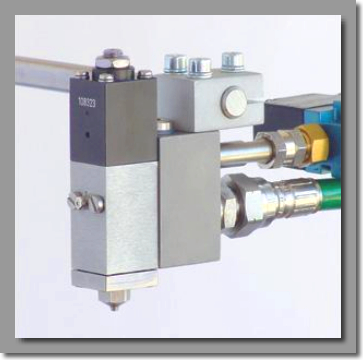

Robatech ACX 100 Series Cold Glue Jetting Heads

For the application without contact of cold glues in the low- to medium-viscosity range at a high system pressure. For precise dot and line applications as required in the packaging, printing and cardboard processing industries.

Applications

The applicator heads of the Robatech ACX100 series are suitable for the application without contact of low- to medium-viscosity dispersion-type and other cold glues. They process adhesives with viscosities of up to 5,000mPas at an operating pressure of maximum 100bar.

The cold glue heads enable precise dot and line applications and are primarily used in the packaging, printing and paper processing industries. The application spectrum reaches from the gluing of folding boxes and cardboard articles over the gluing-in of cards and product samples to forms, mailings as well as the production of construction elements, etc.

Function

The adhesive is fed to the supply part by a pump or from a pressurized container. Glue application is effected through the jetting element. In resting position the glue exit is shut off by the valve pin under spring force. Glue can only leave the applicator head when compressed air lifts the valve pin off its seat.

Jetting elements

The jetting elements are available in two versions. Type 296 features a spherical valve tip. Different nozzles can be screwed onto this jetting element. A cover slide is required to ensure that the glue does not dry out and solidify. Jetting elements of type NV, on the other hand, are equipped with a pin-shaped valve tip which shuts off the glue exit at the delivery edge. This means that no cover slide is required for NV elements.

Design

The ACX heads are robust, electro-pneumatically actuated applicator heads of a largely modular design. They consist of a supply part which takes care of the glue and air supply, and one or several jetting elements which apply the cold glue. All parts coming into contact with the adhesive are made of stainless steel or coated aluminum. This means that aqueous adhesives or types containing solvents can also be processed. The heads are of a very slim execution which makes them suitable for use in tight spaces.

Technical data

Working pressure max.: 100 bar

Glue viscosity max.: 5’000 mPas

Switching pulses max.: 80 /sec

Nozzle diameters: 296: 0.3…2.0 mm

NV: 0.2…0.8 mm

Air supply: 5 bar

Air connection: 1/8″ thread

Glue connection: 1/4″ thread

Material: Stainless steel

Advantages

Precise glue application

Compact, slim execution

High switching frequencies

Suitable for high-speed applications

Quantity to be applied is adjustable

Solutions Provider for the Printing Industry, Mailing Industry and Packaging Industry